Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

+86-0317-5673271 ella@cnspipe.com

Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- Home

- Products

- Spiral Steel Pipe

- Spiral Welded Carbon Steel Pipe

- Saw Spiral Welded Carbon Steel Pipe For Sewage

Products

Contact

- Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

- ADD: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- TEL: +86-0317-5673271

- FAX: +86-0317-5673271

- MOBILE: +8615373302068

- EMAIL: ella@cnspipe.com

- ada@cnspipe.com

- leo@cnspipe.net

- vicky@cnspipe.net

- anne@cnspipe.com

Saw Spiral Welded Carbon Steel Pipe For Sewage

- Product Description

Size: WELDED -- 24"-48"

Type: SAW Pipe

Thickness: sch5, sch5s, sch10s, sch10, sch20, sch30, sch40, sch40s, sch80s,STD, SCH60, XS, sch80, sch100, sch120, sch140, sch160, XXS, or as per your requirement

Standard: ASME B36.10, API 5L

Surface: Treatment usually paint black galv, for carbon steel and alloy steel, and for stainless steel we usually dont do anything on the surface

Certification: ISO 9001:2015

Material: 1. Carbon steel: A106 GR.B, A53, A234 WPB, A234 WPC, A420 WPL6, 20#, 10#, Q235 etc.

2. ASTM A403 WP304, 304L, 316, 316L, 321, 1Cr18Ni9Ti, 00Cr19Ni10 etc.

3. ASTM A234 WP12, WP11, WP22, WP5, WP9, WP91, 12 Cr1MoV, 10CrMo910, 15CrMo, 12Cr2Mo1, ect.

- Product Details

Water pressure test: the steel pipe after expanding is tested one by one on the water pressure test machine to ensure that the steel pipe meets the test pressure required by the standard. The machine has the function of automatic recording and storage. 12. Chamfering: machining the pipe ends...

- Brief Introduction

Saw Spiral Welded Carbon Steel Pipe for Sewage (SSAW)

| Size | WELDED--24"-48" |

| Type | SAW Pipe |

| Thickness | sch5, sch5s, sch10s, sch10, sch20, sch30, sch40, sch40s, sch80s, STD, SCH60, XS, sch80, sch100, sch120, sch140, sch160, XXS, or as per your requirement |

| Standard | ASME B36.10,API 5L |

| Materia | 1. carbon steel: A106 GR.B, A53, A234 WPB, A234 WPC, A420 WPL6, 20#, 10#, Q235 etc. 2. Stainless steel: ASTM A403 WP304, 304L, 316, 316L, 321, 1Cr18Ni9Ti, 00Cr19Ni10 etc. 3. Alloy steel: ASTM A234 WP12, WP11, WP22, WP5, WP9, WP91, 12 Cr1MoV, 10CrMo910, 15CrMo, 12Cr2Mo1, ect. |

| Surface Treatment | usually paint black galv, for carbon steel and alloy steel, and for stainless steel we usually dont do anything on the surface |

| Certification | ISO 9001:2015 |

| Packing | In nude |

| Application | Petroleum, chemical, machinery, electric power, shipbuilding, papermaking, construction etc. |

| Port of delivery | Shanghai port, Xingang port, Xiamen port, Ningbo port etc. |

Water Pressure Test: The Steel Pipe After Expanding Is Tested One By One On The Water Pressure Test Machine To Ensure That The Steel Pipe Meets The Test Pressure Required By The Standard. The Machine Has The Function Of Automatic Recording And Storage. 12. Chamfering: Machining The Pipe Ends After Qualified Inspection To Reach The Required Pipe End Groove Size; Ultrasonic Inspection Ⅱ: Root By Ultrasonic Inspection To Check Again After The Straight Seam Welded Steel Pipe In The Hole Diameter, Water Pressure May Produce Defects.

The specification of straight seam welded steel pipe is expressed by nominal caliber and wall thickness, which can be divided into thin-wall straight seam pipe and thick-wall straight seam pipe. According to the shape can be divided into circular, square or shaped pipe. Major executive standards GB/ t3091-2008, GB/ t9711-2008.

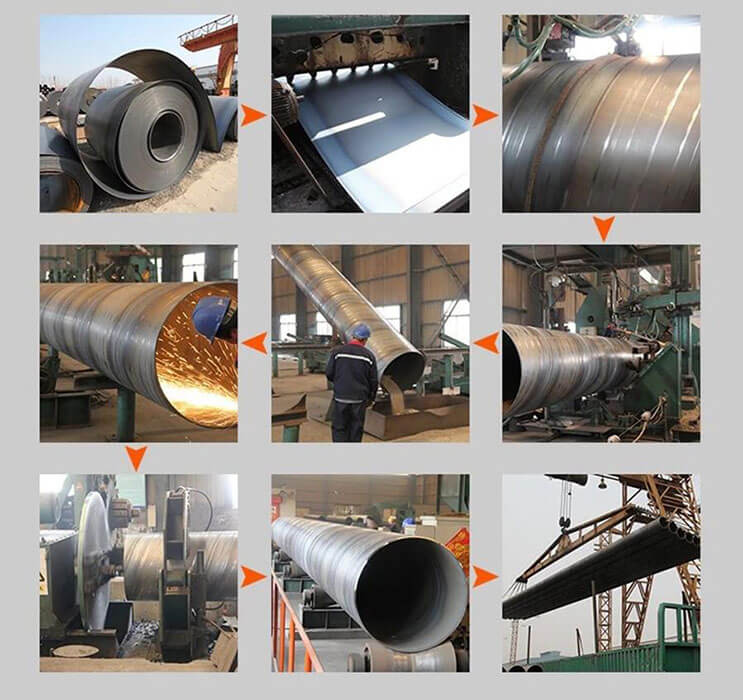

- The Process Flow

- The Application

- The Workshop

- Products List Seamless Steel Pipe Spiral Steel Pipe Longitudinal Welded Steel Pipe Oil Casing Steel Pipe Line Pipe Pile Pipe Steel Structure Pipe Anticorrosion Pipe Learn

- Contact Us Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China Tel: +86-0317-5673271 Fax: +86-0317-5673271 Mob: +86-15373302068E-mail: ella@cnspipe.comada@cnspipe.comleo@cnspipe.netvicky@cnspipe.netanne@cnspipe.com

-

Inquiry

Русский

Русский Français

Français Español

Español English

English Chinese

Chinese