Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

+86-0317-5673271 ella@cnspipe.com

Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- Home

- Products

- Spiral Steel Pipe

- Spirally Welded Pipe Piles

Products

Contact

- Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

- ADD: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- TEL: +86-0317-5673271

- FAX: +86-0317-5673271

- MOBILE: +8615373302068

- EMAIL: ella@cnspipe.com

- ada@cnspipe.com

- leo@cnspipe.net

- vicky@cnspipe.net

- anne@cnspipe.com

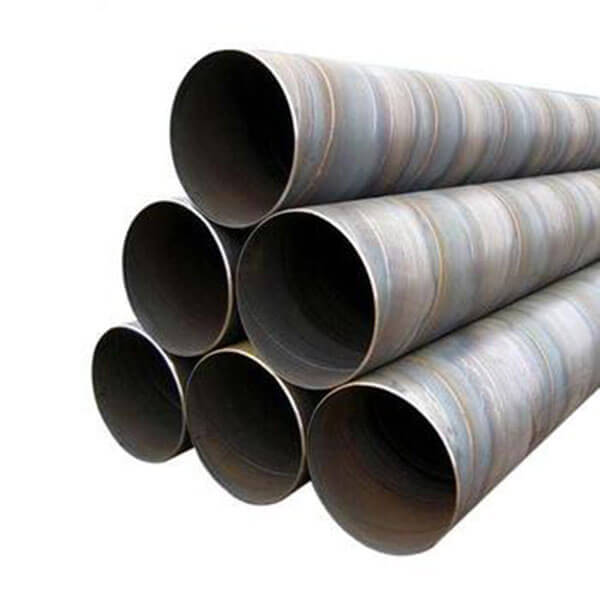

Spirally Welded Pipe Piles

- Product Description

Product name High quality assured spiral

welded steel fluid transport price list available pipe for sale

Thickness: Length 6-30m

Standard: ASTM A500, BS1387, GB3091, ASTMA53, B36.10, BS EN1029, GB/T9711 etc.

Material: API 5L, ASTM A53 GrA, GrB, STKM11, ST37, ST52, 16Mn, etc.

Fabrication Plain ends, cutting, etc.

Surface Treatment: 1. PVC, black and color painting

2. Transparent oil, anti-rust oil

3. According to clients requirement Others We can do special orders as customer's requirement. We also can provide all kinds of steel hollow pipes.

- Product Details

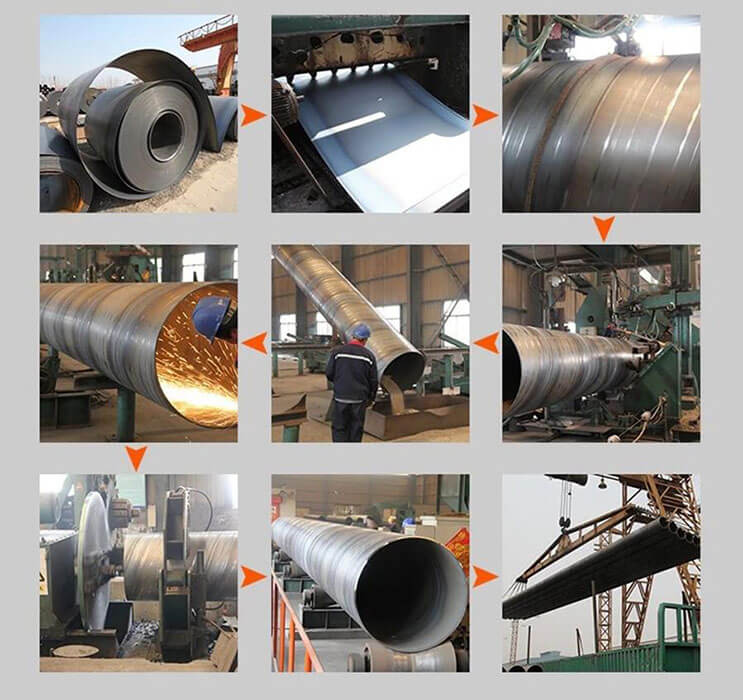

Spiral weld pipe piles are made of steel coiled coil as raw material, which are often heated and extruded, and welded by automatic double-wire double-sided submerged arc welding process.

Spiral weld pipe piles can be applied to water supply engineering, such as petrochemical industry, chemical industry, electric power industry, agricultural irrigation, urban construction.

- Brief Introduction

Spirally Welded Pipe Piles

| Product name | High quality assured spiral welded steel fluid transport price list available pipe for sale |

| Size | Thickness: Length 6-30m |

| Standard | ASTM A500, S1387, GB3091, ASTMA53, B36.10, BS EN1029, GB/T9711 etc |

| Material | API 5L, ASTM A53 GrA, GrB, STKM11, ST37, ST52, 16Mn, etc. |

| Fabrication | Plain ends, cutting, etc |

| Surface Treatment | 1. PVC, black and color painting |

| 2. Transparent oil, anti-rust oil | |

| 3. According to clients requirement | |

| Others | We can do special orders as customer's requirement. |

| We also can provide all kinds of steel hollow pipes. | |

| All the production process are made under the ISO9001:2008 strictly |

High quality carbon structural steelSteel number at the beginning of the two digits of steel carbon content, to uniform carbon content is a few parts per million, such as uniform carbon content of 0.45% steel, steel number for "45", it is not in sequence, so can not be read as 45 steel. Manganese content of high quality carbon structural steel, should be manganese element mark, such as 50Mn. (3) rimming steel, semi-stabilized steel and special purpose high-quality carbon structural steel should be marked at the end of the steel number, such as semi-stabilized steel with a uniform carbon content of 0.1%, the steel number is 10b.

Carbon tool steelSteel number with "T", so as not to mix with other steel. The number in the steel number represents the carbon content, expressed in thousandths of the uniform carbon content. For example, "T8" indicates a uniform carbon content of 0.8%. Mark "Mn" at the end of the steel number, for example, "T8Mn". (4) the phosphorus and sulfur content of high quality carbon tool steel is lower than that of general high quality carbon tool steel.

Wrong side of the reasonThe cause of the wrong side of the large diameter spiral pipe: the wrong side of the large diameter spiral pipe often occurs during the production, and there are many influencing factors. In the production practice, the steel pipe is often degraded by the error edge. Therefore, it is necessary to analyze the causes of the wrong side of large diameter spiral steel pipe and the preventive measures.

Scythe bending of steel belt is the most important factor causing the wrong side of steel pipe. In the spiral welded pipe forming, the scythe bend of the steel belt will change the forming Angle continuously, which will lead to the change of the weld seam gap, resulting in the opening, the wrong side and even the side. It seriously affects the quality of steel pipe, so it is an effective way to reduce the wrong side of steel belt scythe in the production process to observe the scythe bending of steel belt after it is rolled and unrolled. 2. Due to the poor shape and dimensional accuracy of the uncut steel head and tail, it is easy to cause hard bending of the steel belt during butt joint and cause wrong side. 3. the steel head and tail butt welding welding seam height is large, if not handled properly in the process of over molding, easy to cause a large wrong side. 4. Poor edge condition of steel strip is another important reason for wrong edge.

- The Process Flow

- The Application

- The Workshop

- Products List Seamless Steel Pipe Spiral Steel Pipe Longitudinal Welded Steel Pipe Oil Casing Steel Pipe Line Pipe Pile Pipe Steel Structure Pipe Anticorrosion Pipe Learn

- Contact Us Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China Tel: +86-0317-5673271 Fax: +86-0317-5673271 Mob: +86-15373302068E-mail: ella@cnspipe.comada@cnspipe.comleo@cnspipe.netvicky@cnspipe.netanne@cnspipe.com

-

Inquiry

Русский

Русский Français

Français Español

Español English

English Chinese

Chinese