Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

+86-0317-5673271 ella@cnspipe.com

Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- Home

- Products

- Longitudinal Welded Steel Pipe

- ERW Steel Pipe

Products

Contact

- Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

- ADD: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- TEL: +86-0317-5673271

- FAX: +86-0317-5673271

- MOBILE: +8615373302068

- EMAIL: ella@cnspipe.com

- ada@cnspipe.com

- leo@cnspipe.net

- vicky@cnspipe.net

- anne@cnspipe.com

The high frequency straight seam welded steel pipe (ERW Steel Pipe or HFW Steel Pipe) is also called the straight seam resistance welded pipe, the high frequency straight seam welded steel pipe generally produces the caliber is all small, generally under DN600, the large diameter generally USES the double-sided submerged arc welding steel pipe. Its characteristics are: welding speed, welding heat affected area is small, welding on the piece can not clean, welding thin-wall pipe, welding metal pipe.

High-frequency straight seam electric-resistance welded steel pipe(erw steel pipe) is hot-rolled coil after forming machine, the use of high-frequency current skin effect and proximity effects, the tube edge heating and melting, squeeze roller under pressure welding to achieve production. High-frequency resistance welding steel pipe, welding pipe and ordinary welding process is not the same, the weld is made of the base metal melt from the body, the mechanical strength is better than the general pipe. Smooth appearance, high precision, low cost weld high and small, favorable 3PE anti-corrosion coating. There are significant differences in the welding methods between high frequency welded pipe and submerged arc welded pipe. As the welding is done instantly at high speed, the difficulty of ensuring the quality of welding is much higher than that of submerged arc welding.

High frequency straight seam welded steel pipe process: longitudinal shear -- uncoiling -- strip leveling -- head and tail shear -- strip butt welding -- looping material storage -- forming -- welding -- burr removal -- sizing -- flaw detection -- flying cutting -- preliminary inspection -- steel pipe straightening -- pipe section processing -- hydraulic test – flaw detection -- printing and coating -- finished products. High frequency straight seam welded steel pipe is mainly used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, urban construction.

-

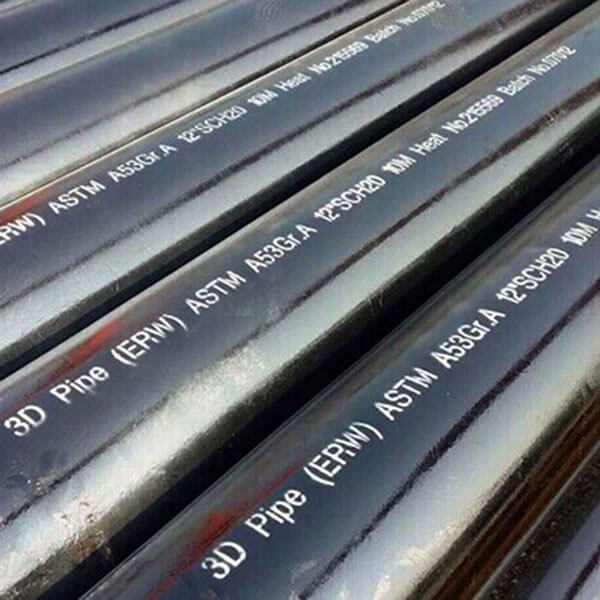

ASTM A53 106b ERW Steel Pipe

NAME: Q235 steel pipe with painting, round 12 inch erw steel pipe, steel tube for buildings materials STANDARD: ASTM, GB, API, JIS, BS, DIN, YB, SNY, etc. MATERIAL: 10#, 20#, 45#, A53A, A53B, A106Gr.A, A106Gr.B, A106A, A106B, ST52, ST358, 16Mn, Q235, Q195, Q345, Q215, API 5L Gr.B, Gr.65, Gr.60, Gr.70, X42, X52, X60, X65, X70, X80,etc.

-

En 10219 ASTM A500 Welded ERW Steel Pipe

Standard: API, ASTM, BS, DIN, GB, JIS, ASTM DIN JIS API GB BS... Standard2: API 5L, ASTM A106-2006, ASTM A213-2001, ASTM A53-2007, BS 1387, DIN 1629/4, GB/T 9711.1-1997, JIS G3454-2007. Grade Group: 10#-45#, 16Mn, A53-A369, Cr-Mo alloy, Mo, Q195-Q345, ST35-ST52, STPG42 Grade: 10#, 20#, 45#, 16Mn, A106(B,C), 34CrMo4, 16Mo, Q195, Q215, Q235, St37, St42, St45, STPG42. Thickness: 6-25mm. Section Shape: Round. Outer Diameter(Round): 219-3200mm. Place of Origin: Hebei, China. Application: Fluid Pipe

-

ASTM A53 ERW Steel Pipe

Standard: JIS, DIN, ASTM, API, GB. Standard2: JIS G3454-2007, JIS G3101, DIN EN 10025, ASTM A106-2006, ASTM A53-2007, ASTM A1020-2002, API 5CT, API 5L, GB/T 8162-1999, GB/T5310. Grade Group: A53-A369, 16Mn, 10#-45#, Mn-V alloy. Grade: A53(A,B), A106(B,C), 16Mn, 20#, 45#, 15MnV. Thickness: 3-50mm. Section Shape: Round. Outer Diameter(Round): 200-3000mm. Place of Origin: China. Application: Fluid Pipe. Technique: SAW. Certification: API

-

ASTM A135 ERW Steel Pipe

Product Name: ERW Hot Rolled. Welded Black Iron Steel astm a135/a795 pipes. OD: 10-600mm(round). Thickness: 1.2-30mm. Material: Q195—Grade B, SS330, SPC, S185 Q215—Grade C, CS Type B, SS330, SPHC Q235---Grade D, SS400, S235JR, S235JO, S235J2 Q345---SS500, ST52. Standard: GB/T13793-1992, GB/T14291-2006, GB/T3091-1993, GB/T3092-1993, GB3640-88 BS1387/1985, ASTM A53/A36, EN39/EN10219, API 5L, GB/T9711.1-99 etc. Zinc coating pre galvanized steel pipe: 60-150g/m2. hot dipped galvanized steel pipe: 200-400g/m2.

ERW Steel Pipe

- Products List Seamless Steel Pipe Spiral Steel Pipe Longitudinal Welded Steel Pipe Oil Casing Steel Pipe Line Pipe Pile Pipe Steel Structure Pipe Anticorrosion Pipe Learn

- Contact Us Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China Tel: +86-0317-5673271 Fax: +86-0317-5673271 Mob: +86-15373302068E-mail: ella@cnspipe.comada@cnspipe.comleo@cnspipe.netvicky@cnspipe.netanne@cnspipe.com

-

Inquiry

Русский

Русский Français

Français Español

Español English

English Chinese

Chinese