Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

+86-0317-5673271 ella@cnspipe.com

Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- Home

- Products

- Longitudinal Welded Steel Pipe

- ERW Steel Pipe

- ASTM A53 106b ERW Steel Pipe

Products

Contact

- Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

- ADD: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- TEL: +86-0317-5673271

- FAX: +86-0317-5673271

- MOBILE: +8615373302068

- EMAIL: ella@cnspipe.com

- ada@cnspipe.com

- leo@cnspipe.net

- vicky@cnspipe.net

- anne@cnspipe.com

ASTM A53 106b ERW Steel Pipe

- Product Description

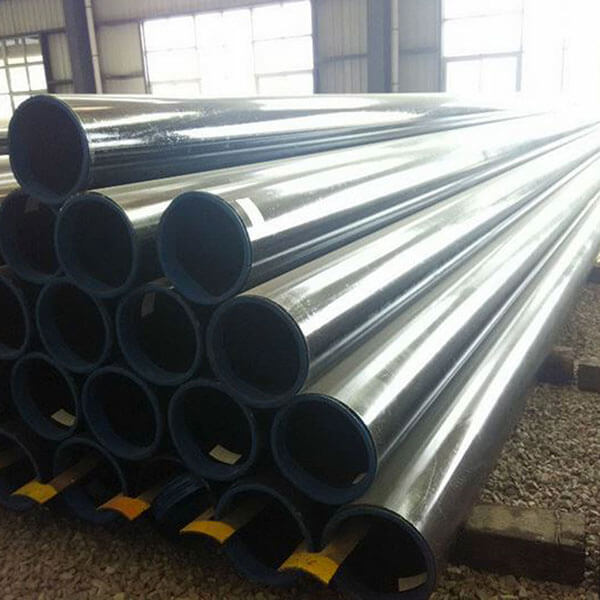

NAME Q235 steel pipe with painting, round 12 inch erw steel pipe, steel tube for buildings materials STANDARD ASTM, GB, API, JIS, BS, DIN, YB, SNY, etc. MATERIAL 10#, 20#, 45#, A53A, A53B, A106Gr.A, A106Gr.B, A106A, A106B, ST52, ST358, 16Mn, Q235, Q195, Q345, Q215, API 5L Gr.B, Gr.65, Gr.60, Gr.70, X42, X52, X60, X65, X70, X80, etc. SPECIFICATION Outer diameter: 15mm-1626mm Wall thickness: 2mm-30mm Length: 6m-12m or as requested SEAM SAW (Spiral welded), SSAW (Spiral submerged-arc welded), HSAW (Helical Submerged Arc Welded), ERW. SURFACE Black painted, PE/PVC/PP coated. Galvanized, color coated, anti rust varnished, anti rust oiled, checkered, epoxy coating, etc. END plain end, spigot & socket joint, beveled, cut square, flanged, piling shoes

- Product Details

ASTM A53 106b ERW Steel Pipe Q235 steel pipe with painting, round 12 inch erw steel pipe, steel tube for buildings materials ERW welding round pipes also are called as Electric Resistance Welded Pipes. This type of steel pipes and tubes are widely used in various fields such as engineering purposes, fencing, scaffolding,...

- Brief Introduction

ASTM A53 106b ERW Steel Pipe

ASTM A53 106b ERW Steel Pipe welding round pipes also are called as Electric Resistance Welded Pipes. This type of steel pipes and tubes are widely used in various fields such as engineering purposes, fencing, scaffolding, line pipes etc. ASTM A53 106b ERW Steel Pipe and tube are available in various qualities, wall thicknesses, and diameters of the finished pipes.

While manufacturing ASTM A53 106b ERW Steel Pipe, there are some strictly standard: high-quality, continuous-cast, fully killed, control-rolled, fine-grain, low-carbon steel. High performance ASTM A53 106b ERW Steel Pipe and tubing possess high strength corrosion resistance, high deformability, high strength and high toughness.

ASTM A53 106b ERW Steel Pipe is available with square ends or beveled for welding, threaded and coupled and victaulic grooved.

Surface finish are available in black or bare, or with protective coatings

| NAME | Q235 steel pipe with painting, round 12 inch erw steel pipe, steel tube for buildings materials |

| STANDARD | ASTM, GB, API, JIS, BS, DIN, YB, SNY, etc |

| SPECIFICATION | Outer diameter: 15mm - 1626mm Wall thickness: 2mm - 30mm Length: 6m - 12m or as requested |

| SEAM | SSAW (Spiral welded), SSAW (Spiral submerged-arc welded), HSAW (Helical Submerged Arc Welded), ERW. |

| SURFACE | Black painted, PE / PVC / PP coated, Galvanized, color coated, anti rust varnished, anti rust oiled, checkered, epoxy coating, etc. |

| END | plain end, spigot & socket joint, beveled, cut square, flanged, piling shoes |

| END PROTECTOR | 1) Plastic pipe cap 2) Iron protector |

| PACKAGE | Standard export package, suit for all kinds of transport or as required. |

| PRICE TERM | EXW, FOB, CFR, CIF, etc. |

| PAYMENT TERM | T/T, L/C at sight, etc. |

| APPLICATION | 1) General service for industries petroleum, chemical, aviation, etc. 2) Fluid, gas and oil transport. 3) Press and heat transmission. 4) City construction, etc. |

| CONTACT | Please inform us if any item is interesting to you. |

A53 PIPE Specifications

A/SA53

NPS 1/4″ – 30″

Schedules 10 through 160, STD, XH and XXH

ASTM A53 pipe (also referred to as ASME SA53 pipe) is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas and air lines. It is suitable for welding and for forming operations involving coiling, bending, and flanging, subject to certain qualifications.

American Piping Products stocks a full range of A53 pipe (SA53 Pipe) in:

*Grade B

*NPS ¼"”" to 30” diameter

*Schedules 10 through 160, STD, XH and XXH

Scope

ASTM A53 106b ERW Steel Pipe covers Seamless and Welded, Black and Hot-Dipped Galvanized nominal (average) wall pipe for coiling, bending, flanging and other special purposes and is suitable for welding. Continuous-Welded pipe is not intended for flanging. Purpose for which pipe is intended should be stated on order.

Looking for specific post-production services? See our full list.

Materials and Manufacture

The steel for both ASTM A53 106b ERW Steel Pipe shall be made by one or more of the following processes: open-hearth, electric furnace, or basic-oxygen. The weld seam of electric-resistance welded pipe in Grade B shall be heat treated after welding.

Chemical Requirements

Download Chart

| Type S (seamless) | Type E | Type F | |||

| (electric-resistance welded) | (furnace-welded pipe) | ||||

| Grade A | Grade B | Grade A | Grade B | Grade B | |

| Carbon max. % | 0.25 | 0.30 | 0.25 | 0.30 | 0.30 |

| Manganese % | 0.95 | 1.2 | 0.95 | 1.2 | 1.2 |

| Phosphorous, max. % | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Sulfur, max. % | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| Copper, max.% | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 |

| Nickel, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 |

| Chromium, max. % | 0.40 | 0.40 | 0.40 | 0.40 | 0.40 |

| Molybdenum, max. % | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Vanadium, max. % | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

Permissible Variations in Wall ThicknessHot-Dipped Galvanizing

Sets standards for coating of ASTM A53 106b ERW Steel Pipe with zinc inside and outside by the hot-dipped process. Weight of coating must not average less than 1.8 oz. per square foot and not less than 1.6 oz. per square foot.

The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

Permissible Variations in Weights per Foot

Plus or minus 10%

Permissible Variations in Outside Diameter

Outside Diameter at any point shall not vary from standard specified more than:

| For NPS 1 1/2 and Smaller Sizes | For NPS 2 and Larger Sizes | ||

| 1/64″ | 1/32″ under | 1% over | 1%under |

| Seamless and Electric-resistance-welded | Continuous-Welded | ||

| Grade A | Grade B | ||

| Tensile Strength, min., psi | 48,000 | 60,000 | 45,000 |

| Yield Strength, min., psi | 30,000 | 35,000 | 25,000 |

Number of Tests Required

Seamless and ASTM A53 106b ERW Steel Pipe — Bending, flattening, tensile on one length of pipe from each lot of 500 lengths or less of a size. Continuous-Weld — Bending, flattening, tensile

| NPS 1 1/2 & smaller | NPS 1 1/2 & smaller |

| one / 25 tons | one / 50 tons |

Hydrostatic Testing

Hydrostatic inspection test pressures for ASTM A53 106b ERW Steel Pipe plain end and threaded and coupled pipe are specified.

Hydrostatic pressure shall be maintained for not less than 5 seconds for all sizes of seamless and electric-resistance-weld pipe.

Mechanical Tests Specified

Tensile Test — Transverse required on ERW for NPS 8 and large. Sending Test (Cold) — STD and XS-NPS 2 and under XXS-NPS 1 1/4 and under.

| Degree of Bend | Diameter of Mandrel | |

| For Normal A53 Uses | 90 | 12 x nom dia. of pipe |

| For Close Coiling | 180 | 8 x nom dia. of pipe |

Flattening Test — NPS 2 and larger STD and XS. (Not required for XXS pipe.)

ASTM A53 106b ERW Steel Pipe Lengths

| Standard Weight | Single Random — 16′ – 22′. 5% may be jointers. If Plain Ends — 5% may be 12′ – 16′. |

| Double Random — Shortest Length 22′, minimum average for order 35′. | |

| Extra Strong and Double Extra Strong | Single Random — 12′ -22′. 5% may be 6′ – 12′. |

| Double Random (XS and lighter) — Shortest Length 22′, minimum average for order 35′. | |

| Lengths longer than single random with wall thicknesses heavier than XS subject to negotiation. |

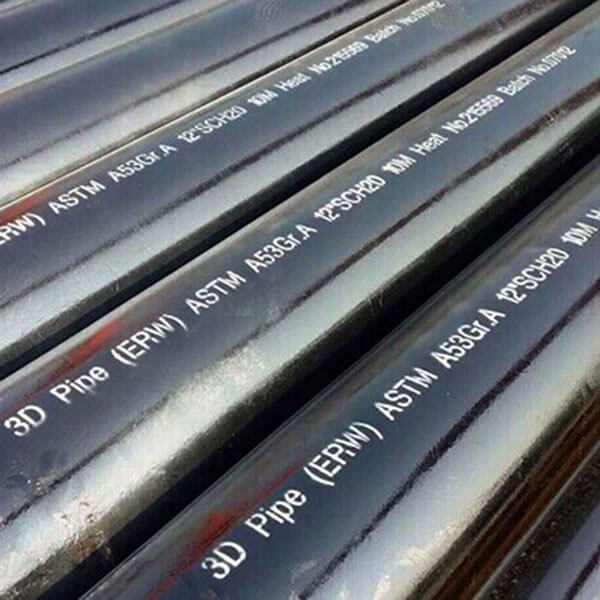

Required Markings on Each Length

(On Tags attached to each ASTM A53 106b ERW Steel Pipe Bundle in case of Bundled Pipe)

| Rolled, Stamped, or Stenciled (Mfrs. Option) |

| Name brand of manufacturer |

| Kind of pipe, that is, Continuous Welded, Electric-Resistance-Welded A, Electric-Resistance-Welded B, Seamless A, Seamless B, XS for extra strong, XXS for double extra strong. |

| ASTM 53 |

| Length of pipe |

General Information

| Couplings — Applied handling tight. Couplings, 2″ and smaller straight tapped, other sizes taper tapped. | |

| Thread Protection — Applied to pipe 4″ and larger. | |

| End Finish (unless otherwise specified) — | STD or XS, or wall thicknesses less than 0.500 in. (excluding XXS): Plain and beveled |

| All XXS and wall thicknesses over 0.500 in: Plain end square cut. | |

Product Details

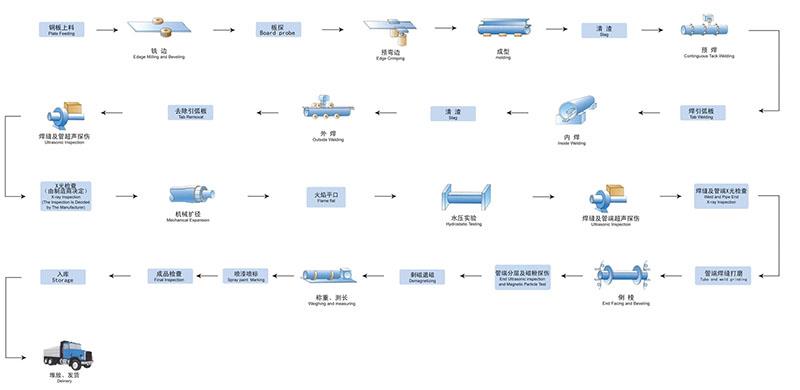

Product Manufacturing Process

Product Size

Certifications Of Product

- Product Applications

- Products List Seamless Steel Pipe Spiral Steel Pipe Longitudinal Welded Steel Pipe Oil Casing Steel Pipe Line Pipe Pile Pipe Steel Structure Pipe Anticorrosion Pipe Learn

- Contact Us Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China Tel: +86-0317-5673271 Fax: +86-0317-5673271 Mob: +86-15373302068E-mail: ella@cnspipe.comada@cnspipe.comleo@cnspipe.netvicky@cnspipe.netanne@cnspipe.com

-

Inquiry

Русский

Русский Français

Français Español

Español English

English Chinese

Chinese