Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

+86-0317-5673271 ella@cnspipe.com

Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- Home

- Products

- Longitudinal Welded Steel Pipe

- ERW Steel Pipe

- En 10219 ASTM A500 Welded ERW Steel Pipe

Products

Contact

- Cangzhou Steel Pipe Group (CSPG) Co., Ltd.

- ADD: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China

- TEL: +86-0317-5673271

- FAX: +86-0317-5673271

- MOBILE: +8615373302068

- EMAIL: ella@cnspipe.com

- ada@cnspipe.com

- leo@cnspipe.net

- vicky@cnspipe.net

- anne@cnspipe.com

En 10219 ASTM A500 Welded ERW Steel Pipe

- Product Description

Standard: API, ASTM, BS, DIN, GB, JIS, ASTM DIN JIS API GB BS... Standard2: API 5L, ASTM A106-2006, ASTM A213-2001, ASTM A53-2007, BS 1387, DIN 1629/4, GB/T 9711.1-1997, JIS G3454-2007 Grade Group: 10#-45#, 16Mn, A53-A369, Cr-Mo alloy, Mo, Q195-Q345, ST35-ST52, STPG42 Grade: 10#, 20#, 45#, 16Mn, A106 (B,C), 34CrMo4, 16Mo, Q195, Q215, Q235, St37, St42, St45, STPG42 Thickness: 6-25 mm Section Shape: Round Outer Diameter (Round): 219-3200 mm Place of Origin: Hebei, China Application: Fluid Pipe

- Product Details

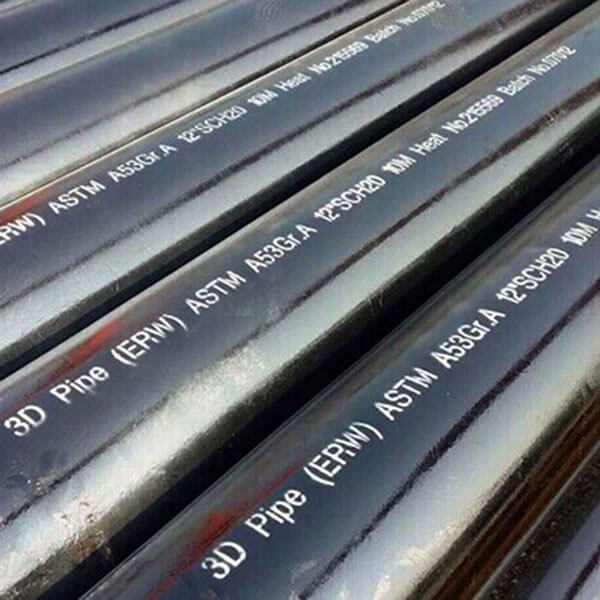

Generally speaking, high-frequency welded pipe is included in ERW welded pipe, which is a kind of ERW welded pipe produced by high-frequency welding process. ERW welded pipe is a kind of economical steel pipe with advanced performance and leading quality in the field of oil and gas storage and transportation.

- Brief Introduction

| Products Details | |||||

| Commodity | EN 10219 ASTM A500 Welded ERW Steel Pipe | ||||

| Outer diameter | ERW / HFW | LSAW / DSAW | SSAW / HSAW | RHS | SHS |

| 1/8-20 inch (10.3-508 mm) | 2-56 inch (323.8-1,420 mm) | 8-126 inch (219.1-3,200 mm) | 40 x 20 mm - 1,000 x 800 mm | 15 x 15 mm - 1,000 × 1,000 mm | |

| Wall thickness | 0.4-16 mm | 6.0-40 mm | 6.0-26 mm | 1.0-30 mm | 0.6-30 mm |

| Length | 5.8 ~ 12.0 m or upon customers' requirements EN 10219, API 5L, DIN 1626/1615, DIN 17120, etc. | ||||

| Standard | GB/T 3091, GB/T 13793, ASTM A252, ASTM A53, ASTM A500, EN 10210, EN 10219, API 5L, DIN 1626/1615, DIN 17120, etc. | ||||

| Grade | SS400, Q235, Q345, Q460, A572 Gr.50, A572 Gr.60, S235, S275, S355, Grade A/B, X42, X52, X60, X70, etc. | ||||

| Surface | Prime quality (bared, oiled, color paint, 3LPE, or other anti-corrosive treatment) | ||||

| Inspection | With Chemical Composition and Mechanical Properties Analysis; Dimensional and Visual Inspection, also with Nondestructive Inspection. | ||||

| Application | structure, electric power transmission tower projects, piling, water, oil & gas pipeline engineering, mechanical industry, municipal projects, roads and its auxiliary facilities, etc. | ||||

| Packing | Standard export, in bulk / bundles / nylon fabric bags with seaworthy packing; or according to customers' requestments. | ||||

| Delivery Time | 1. 20-45 days after received deposit or confirmed L/C 2. Depends on your oder quantity | ||||

| Payment Terms | 1. T/T: 30% T/T advance, 70% balance copy of B/L 2. L/C: at sight 3. T/T and L/C: 30% T/T advance, 70% L/C | ||||

| Port | China main port | ||||

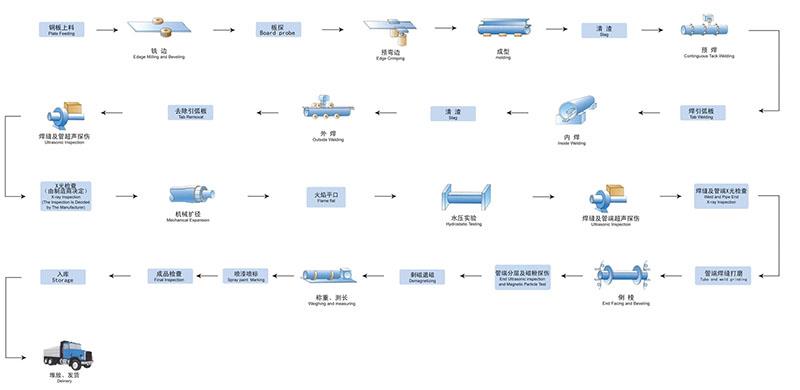

Product Manufacturing Process

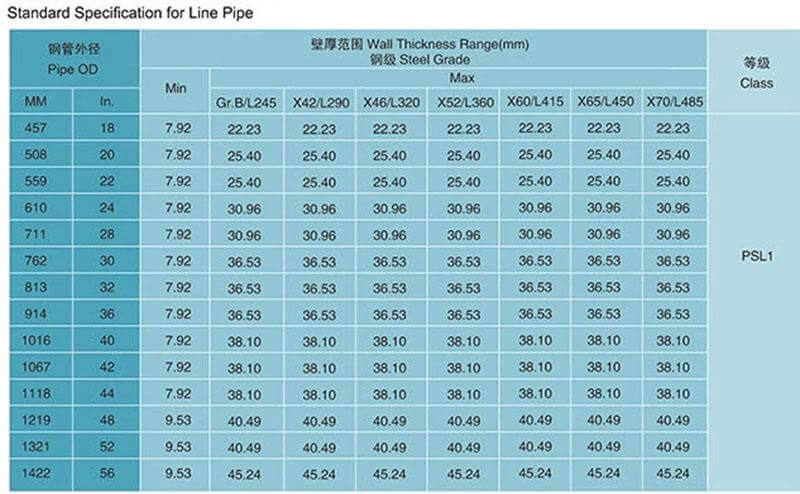

Product Size

Product Details

Certifications Of Product

- Product Applications

- Products List Seamless Steel Pipe Spiral Steel Pipe Longitudinal Welded Steel Pipe Oil Casing Steel Pipe Line Pipe Pile Pipe Steel Structure Pipe Anticorrosion Pipe Learn

- Contact Us Address: No.92 Jiefang East Rd., Cangzhou City, Hebei Province, China Tel: +86-0317-5673271 Fax: +86-0317-5673271 Mob: +86-15373302068E-mail: ella@cnspipe.comada@cnspipe.comleo@cnspipe.netvicky@cnspipe.netanne@cnspipe.com

-

Inquiry

Русский

Русский Français

Français Español

Español English

English Chinese

Chinese